Electric Heat Press Platen Manufacturer

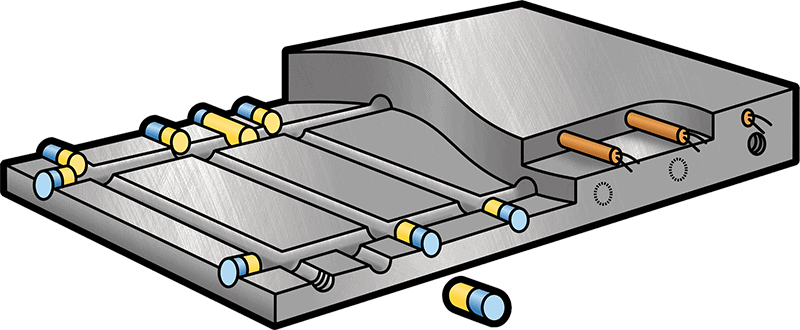

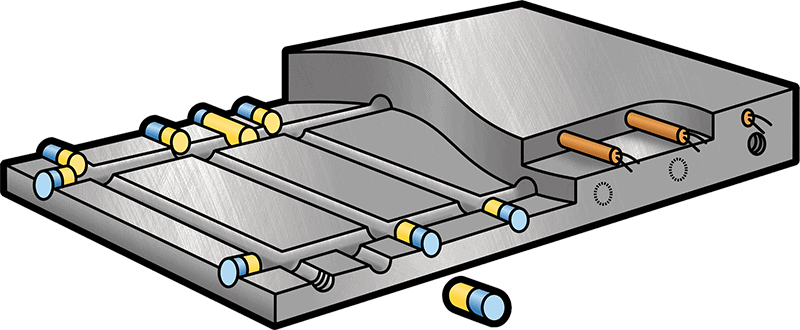

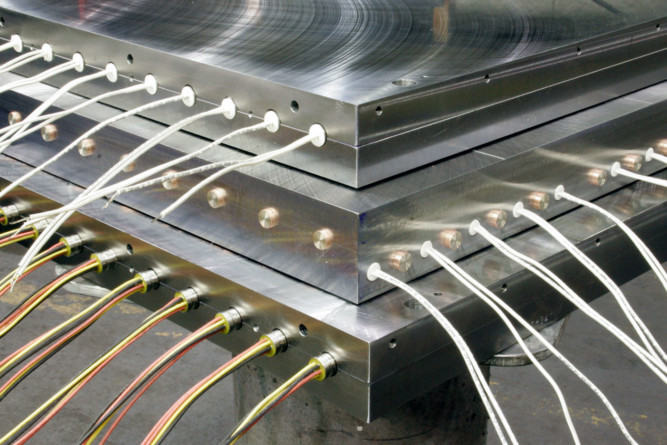

MultiZone Platens

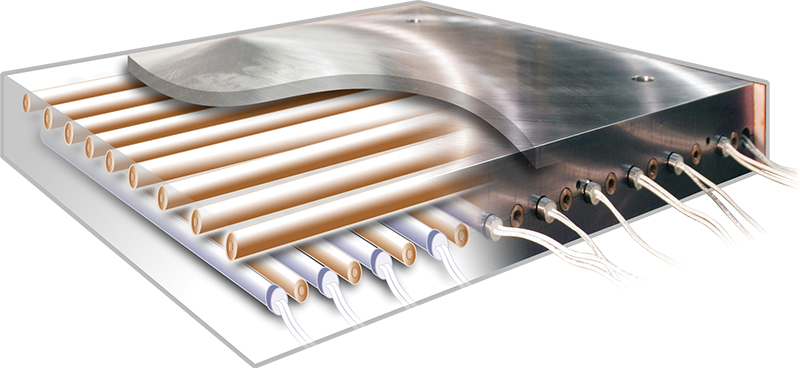

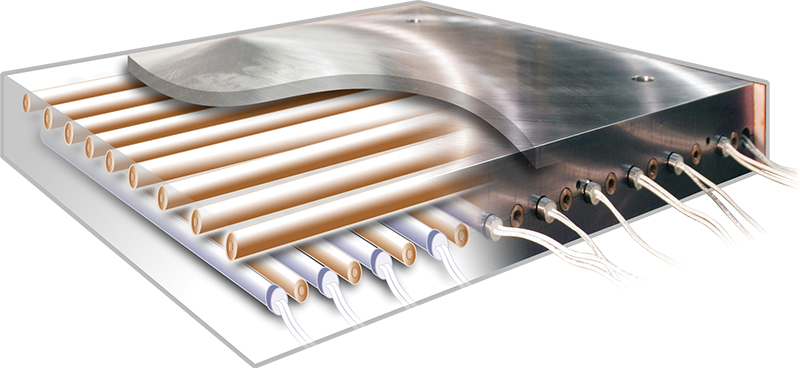

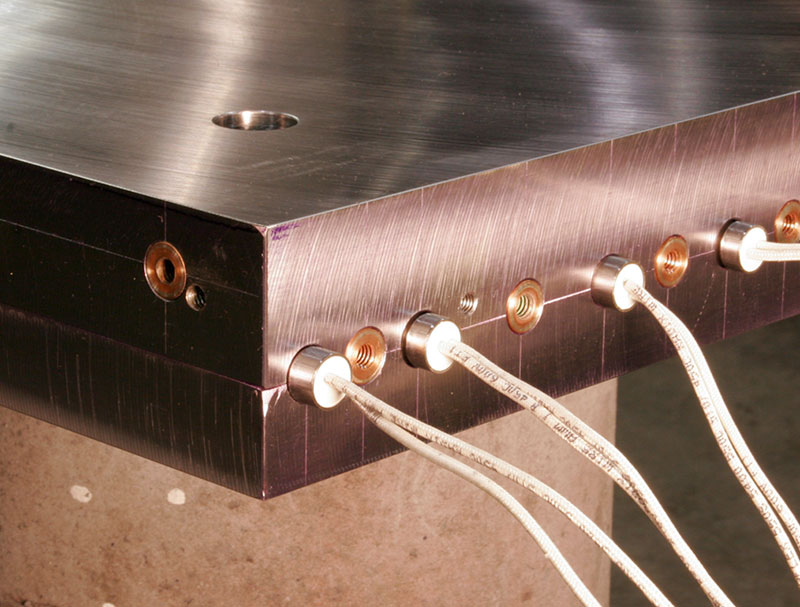

Heat Tube Platens

Electric Platen Types

Single & MultiZone Control Panels

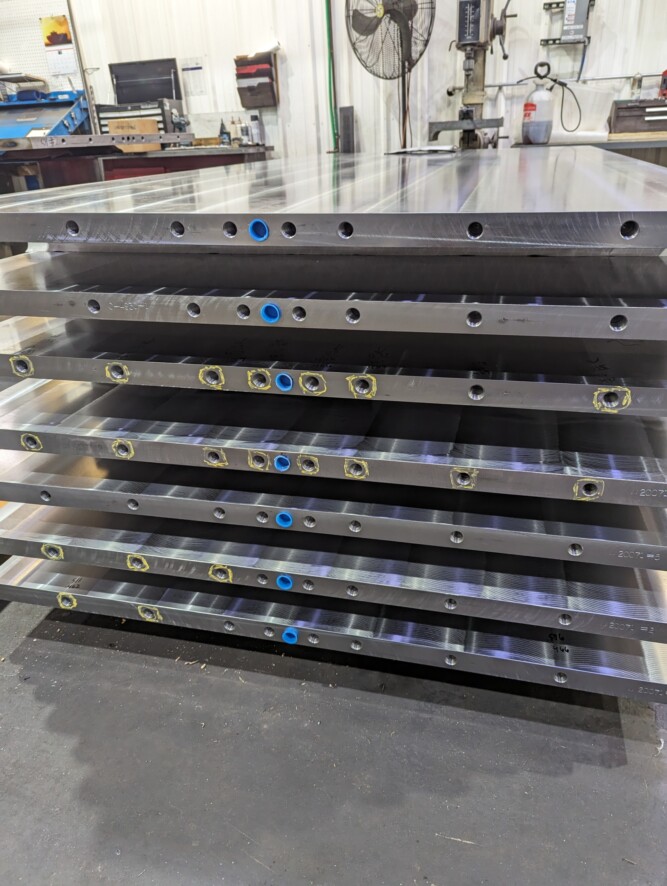

Electric Platen Manufacturing

Over 50 years of Electric Platen Production

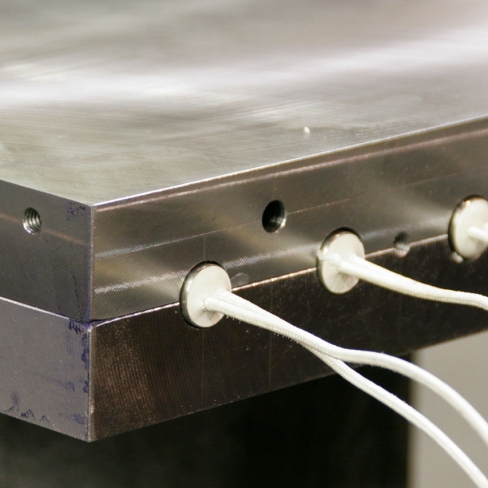

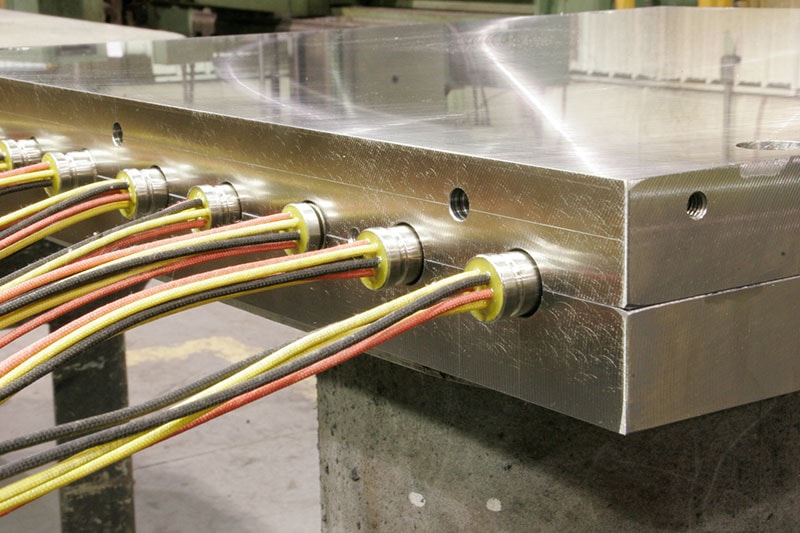

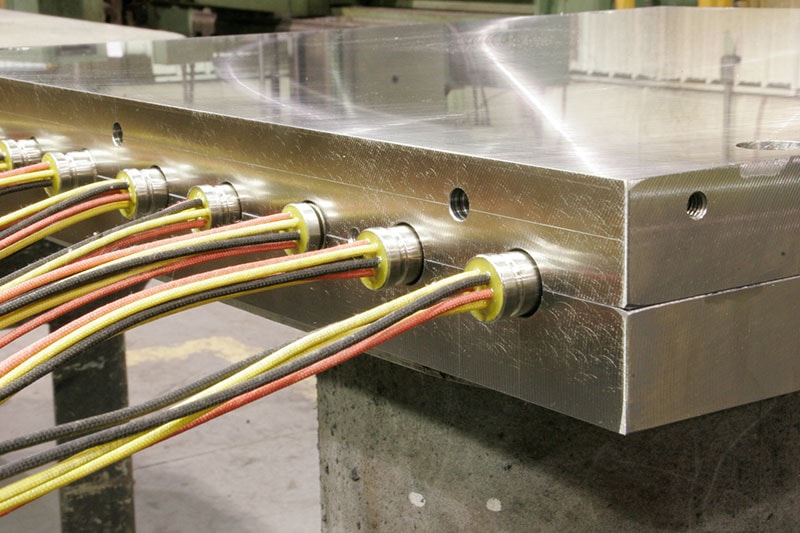

Whether cartridge or strip, single or MultiZone, Venango Machine Company’s electric platens offer compression molders an alternative heating method that allows for faster heat up and recovery times and higher temperatures, as opposed to traditional heating methods. Most importantly, each and every electric platen we manufacture is custom-designed by our skilled team of engineers to meet your specific needs.

Venango Machine Company also designs and manufactures steam and thermal fluid platens, as well as electrically heated, water-cooled platens (Type EWC). To read more about the characteristics of these platens, please visit our Steam & Thermal Fluid Platens page.

Gallery

Markets Served

Electric Platen Types: Electric Platen Manufacturing

Operating temperature and temperature uniformity are important when determining what type of electric platen is needed for your platen application. Determine whether your application needs platens that heat only or requires both heating and cooling. Consider which type of heater is preferred and best meets your needs. The chart below shows the difference between the types of electric platens that are available. If you are unsure which type of electric platen is best for your application, contact our sales department for further assistance.

Type SE - Strip Electric Platen

Type CE - Cartridge Electric Platen

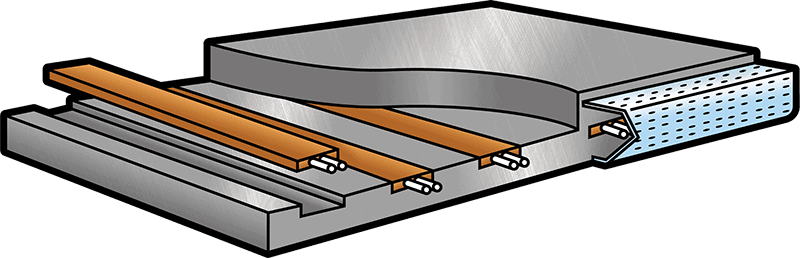

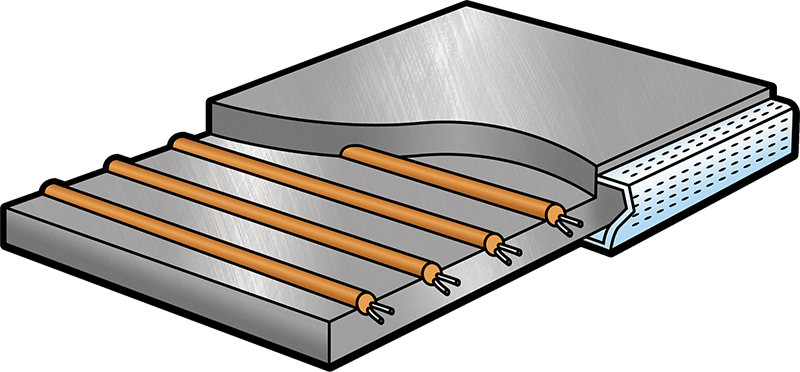

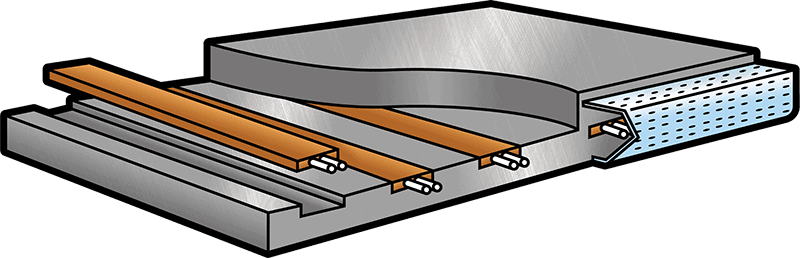

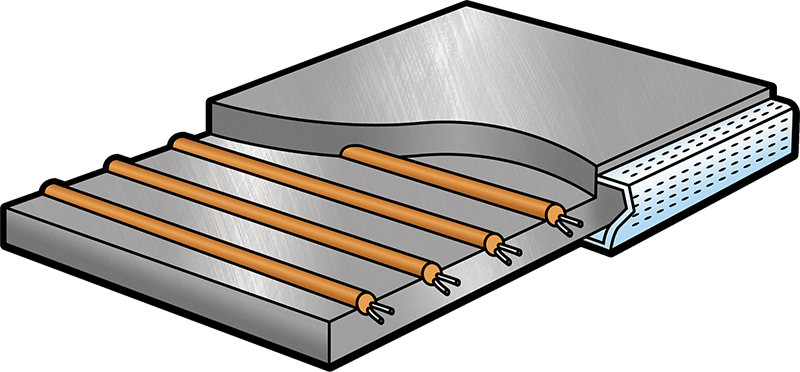

Type HT - Heat Tube Platen

Type EWC - Electrically Heated, Water Cooled Platen

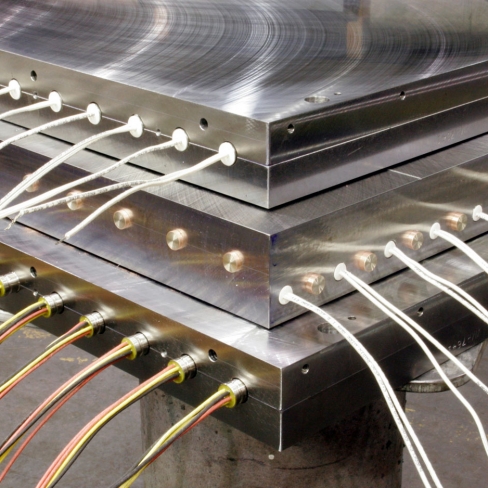

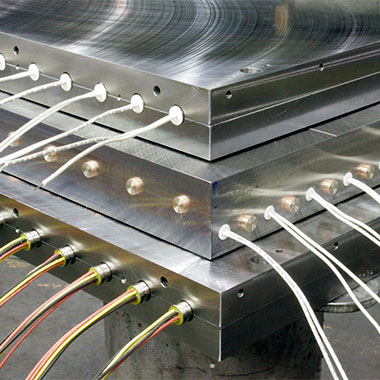

MultiZone Platens: The Best Platens for Temperature Control & Uniformity

When temperature uniformity is critical, the MultiZone Platen is your ultimate solution. Complete with a control panel, this Venango Machine Company-exclusive technology delivers the precision control necessary to ensure a quality product and faster recovery times, saving you valuable time and money. In fact, you’ll find our custom-designed MultiZone Platens are developed with your most intricate requirements — and your complete satisfaction — in mind.

Maintaining good temperature uniformity over the surface of a platen is extremely difficult. At Venango, our exclusive MultiZone Platen technology makes platen heat control much easier and much more precise. This enables you to control the platen temperature, and ultimately, the quality of your product. If temperature control is your problem, the MultiZone Platen is the answer.

Customer Testimonials for the Multizone Platen:

- We consider MultiZone part of our competitive advantage.

- MultiZone reduced mold surface temperature variation by almost 400%.

- MultiZone is superior to heat tube technology because the key is uniform mold temperature, not uniform platen temperature. The heat tube platen does not give manufacturers that capability, but MultiZone does.

- Production is a function of time, temperature, and pressure. MultiZone has eliminated variation of temperature from the manufacturing equation.

- The MultiZone operator screen user interface makes it easier for the operator to directly control temperature on the mold surface.

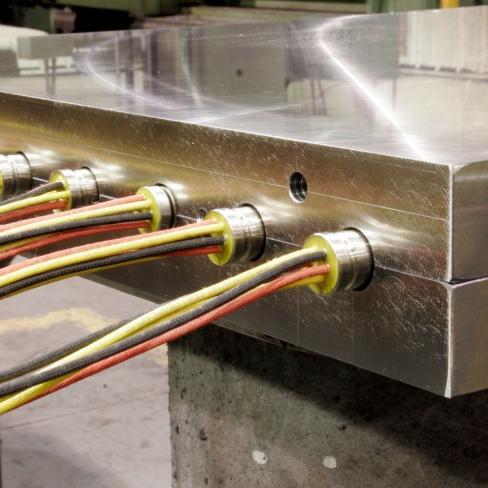

Single Zone and MultiZone Platen Control Panels

Looking for precise controls for your electric platens? Venango Machine Company offers a number of solutions:

- Initial control panel engineering design and specifications

- Stand-alone control panel options

- Single-zone control panel options with complete operator interface HMI system

- MultiZone control panel options with complete operator interface HMI system

- Control panel schematics

- On-site setup and training for electric platen control panels

- On-site troubleshooting for electric platens and control panels

Regardless of your requirements, Venango Machine Company is a one-stop shop for all your control panel needs.

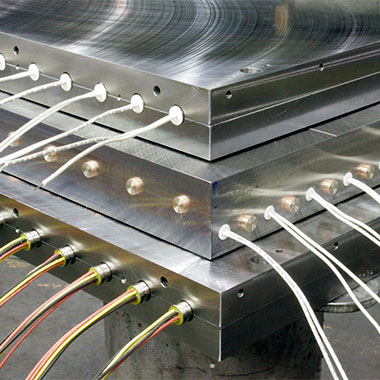

Cost-Effective Heat Tube Platens

At Venango, our heat tube platen technology distributes cartridge heat energy with an amazing uniformity, reducing scrap costs, producing higher quality molded materials, and allowing for faster cycles. In fact, our heat tube platens exceed the most stringent industry heat distribution standards for single-zone platen designs.

Designed in a multi-layer lattice of cartridge heaters/heat tubes, our heat tube platens are extremely cost-effective when utilized with your existing control system for retrofitting projects. What’s more, they can be quickly and easily adapted to your existing press equipment. Contact us today to learn more about what Venango Machine Company can do for you.

Electric Platen Repair & Refurbishing

Due to operational efficiencies, it is critical that platens maintain their flatness and parallelism. If a platen is even slightly bent or damaged, it is going to produce imperfections in the end product. Venango Machine Company’s refurbishing program is capable of re-machining electric platens that have been damaged in pressing accidents, upgrading hanger and guide systems to accommodate additional press openings, and restoring flat/parallel specifications to platens experiencing normal wear and tear. To learn more about Venango’s platen refurbishing capabilities, contact us today.

Contact us Today for any of your Electric Platens Needs

Related News

MultiZone Platens With the Best Heat Uniformity and Temperature Control

Venango’s heated platens with even temperature control allow manufacturers to introduce zone-specific temperatures while applying forming pressure to molds or directly to materials. This heat uniformity is crucial, as it…

Choosing the Best Electric Heated Platen For Your Application

When searching for the best type of electric platen for your application, it is important to consider some crucial factors, such as operating temperature and whether the platen should excel…

American-Made Plywood Platens

American-Made Plywood Platens Venango Machine Company is a leading manufacturer of premium American-made plywood platens for producing plywood, MDF, OSB, and other composite wood products. The high-quality platens for the…

Wickert Press Platen Manufacturer

Venango is a Leading Wickert Press Platen Manufacturer Wickert is one of the top press manufacturers worldwide and Venango maintains a comprehensive understanding of their equipment. If you are looking…

Platens for Heated Compression Molding Presses

Since 1954 Venango Machine Company has been at the forefront of developing new technology critical for subsequent advancements in the rubber, laminate, composite, and plywood industries. One of the manufacturing…

Multi-Zone Electric Platens for Carbon Fiber Manufacturers

Multi-Zone Electric Platens for Carbon Fiber Manufacturers Carbon Fiber Manufacturers Requiring Multi-Zone Electric Platens Throughout history, there have been pivotal moments where the discovery or invention of new materials revolutionized…

Steam & Thermal Fluid Platens for Wood Panels

Steam & Thermal Fluid Platens for Wood Panel Manufacturers Wood Panel Platen Manufacturing with Venango Venango Machine Company opened its doors in 1954 and through a dedication to continual innovation…

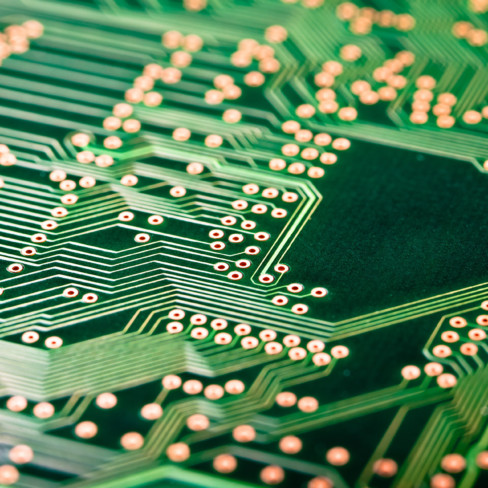

Laminate Industry Press Platens

Laminate Industry Press Platen Manufacturing Whether you are a company manufacturing copper clad laminates, simply making prepreg, or producing complete circuit boards, Venango is your source for custom platens….

Custom Platens for Golf Ball Core Manufacturing

Custom Platens for Golf Ball Core Manufacturing Your golf ball manufacturing business needs cores that are produced with the right weight and shape on every press. Venango platens can help…

High Temperature Electric Platens

High Temperature Electric Platens If your company manufactures products using press equipment that requires high temperatures, Venango can provide you with the perfect custom platen solution. We are expert manufacturers…